CEO Analysis: Essential Supply Chain Management Glossary

Supply Chain Management (SCM) is no longer just "procurement + logistics" back-office work, but a core capability that determines whether enterprises can deliver stably, maintain margins, and resist risks. After multiple global disruptions from COVID, wars, and AI black swan events in recent years, supply chains have become more fragile and complex. To stabilize operations, the first step isn't blindly implementing new systems—it's unifying corporate language, so the entire organization understands where you want the company to go and which benchmarks to align with. Because how you define problems determines how you design processes and KPIs.

This article presents a concise "terminology guide," organizing the most commonly used and easily misunderstood key supply chain terms from recent years (also mainly for my own learning notes 🤫).

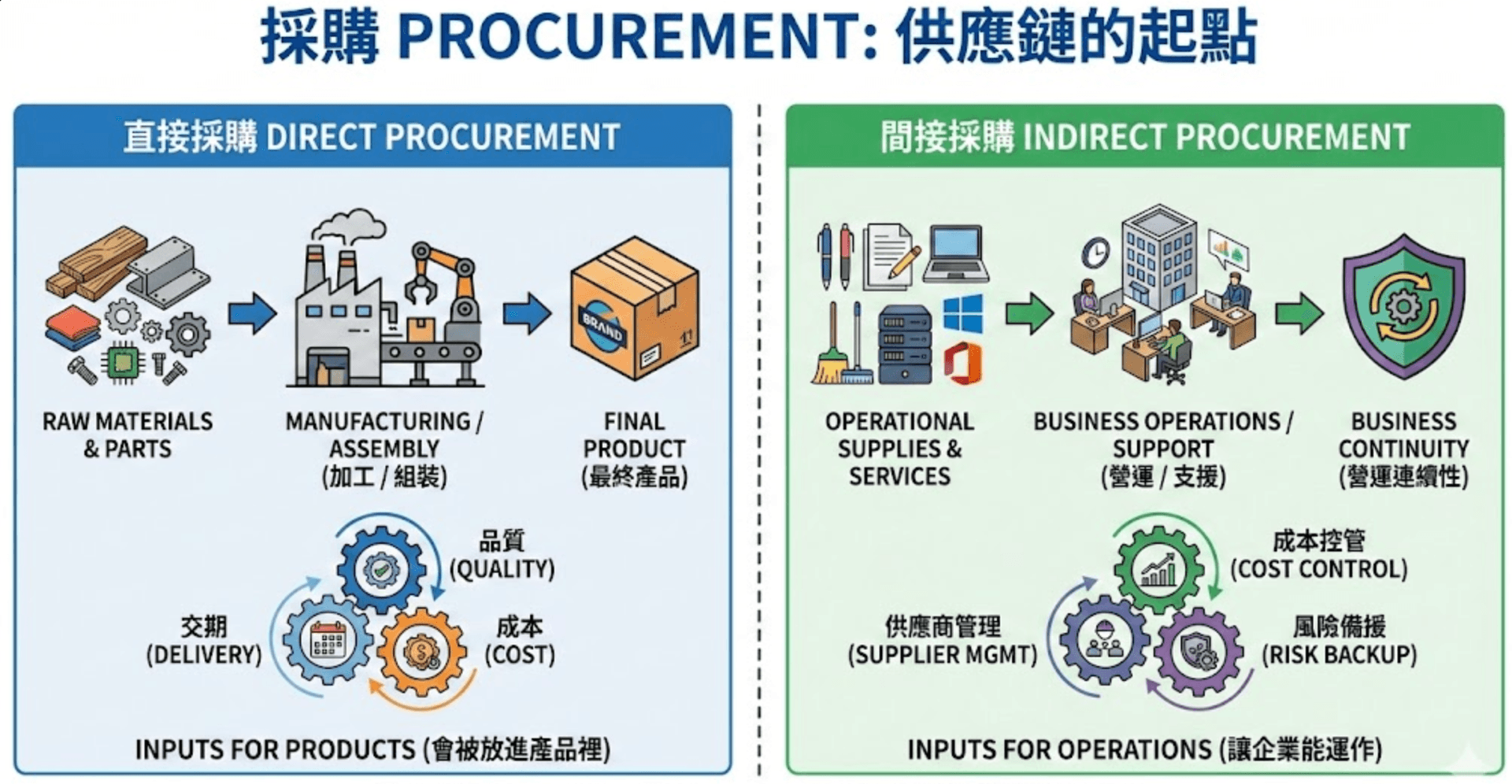

▍Procurement: The Starting Point of Supply Chains

Procurement is the strategic process of acquiring resources needed for business operations, usually also the starting point of supply chains. To do procurement clearly, you must first distinguish two fundamentally different types: Direct Procurement and Indirect Procurement.

Direct Procurement

Direct procurement refers to raw materials, components, and services that "will go into the product."

-

Manufacturing: Raw materials, semi-finished goods, work-in-progress (WIP), and any items that need processing or assembly in the factory before becoming final products.

-

Retail/Channels: Finished goods purchased for "resale."

The core challenge of direct procurement is: delivery time, quality, and cost are always interconnected.

Indirect Procurement

Indirect procurement refers to items and services that "won't go into the product" but enable the business to operate, such as office supplies, facility maintenance, administrative systems, and software subscriptions.

It's often underestimated because it's not in the BOM (Bill of Materials), but it has enormous impact on operational continuity and equally requires supplier management, cost control, and risk backup.

▍Supplier Management: Beyond What to Buy, More Important Is Who to Buy From

Procurement is about "what to buy"; Supplier Management is about "who to buy from." When products consist of hundreds or thousands of components, the supplier system is essentially the enterprise's second organizational chart. Once management loosens, risks directly reflect in delivery and quality.

Effective supplier management typically includes three dimensions:

-

Vendor Identification and Stratification: For each critical component, who can supply, who can substitute, where are the risks?

-

Performance Metrics: Regular tracking using quality, cost, delivery, and other indicators.

-

Contingency Planning: If the primary supplier has issues, do you have a validated second supplier (No. 2) or even third supplier (No. 3) ready to step in?

True risk control isn't finding people after problems occur, but maintaining activatable alternative paths in normal times.

▍Inventory and Warehouse Management: From "Acquired" to "Deliverable"

After Procurement is complete, materials become inventory. The core of Inventory Management is: what do you have, where is it, when should you replenish?

Highly coupled with this is Warehouse Management, which handles physical operations and process design within warehouses, including:

-

Storage Logic: Where materials are placed to optimize inbound/outbound flow and movement paths.

-

Tracking Accuracy: System records and physical records must match.

-

Fulfillment (Pick-Pack-Ship): From receiving orders to picking, packing, and shipping—can the entire rhythm remain stable?

Good warehousing isn't about "fitting everything in," but "keeping things flowing." To achieve this, data systems and on-site processes must be synchronized, otherwise you'll get seemingly good but unreliable inventory numbers.

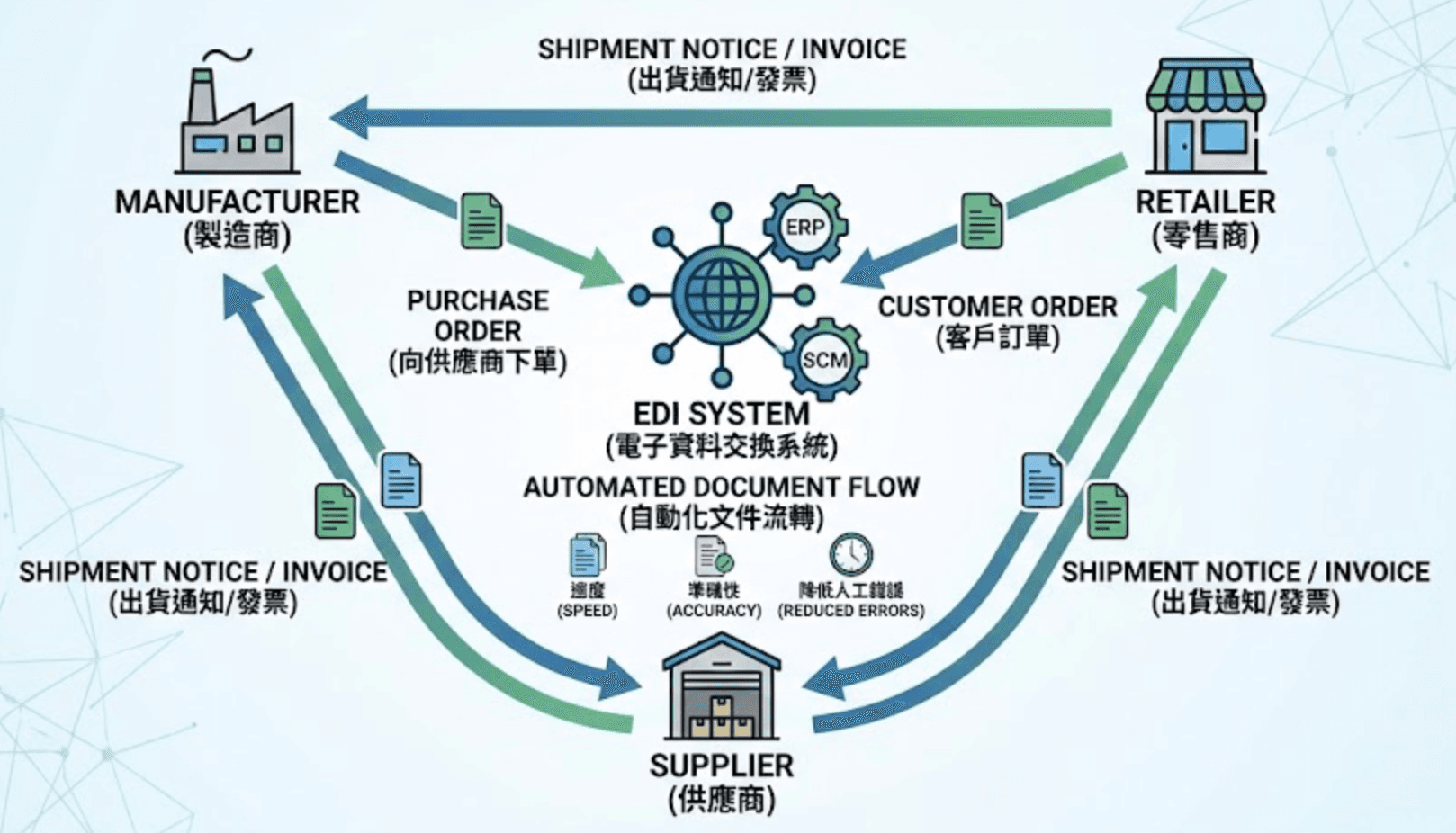

▍EDI: Supply Chain's Standardized "Digital Language"

For speed and accuracy, modern supply chains heavily rely on EDI (Electronic Data Interchange). It's a standardized format for exchanging orders and business documents between enterprises.

Rather than relying on manual email or phone confirmation, enterprises typically use EDI (often integrated in ERP or SCM systems) to:

-

Receive customer orders

-

Place orders with suppliers

-

Automate document flow across networks, reducing manual errors and delays

▍Logistics Management: The Systems Engineering That Makes Goods "Actually Arrive"

Logistics Management handles the physical movement and visibility of raw materials and finished goods through supply chains. It's not just transportation—it's an integration job spanning countries, systems, and regulations.

Common elements include:

-

Transportation: Scheduling of ocean, air, land freight and port nodes.

-

Cross-Border Compliance: Customs declaration, tariffs, regulations, and port requirements.

-

Real-Time Tracking: Using ERP or dedicated SCM systems to monitor transportation status, reducing "black box time."

Good logistics doesn't just bring cost reduction, but makes delivery promises credible, which directly reflects in customer trust and bargaining power.

▍Drop Shipment: Fulfillment Strategy Without Warehouses

Drop Shipment is a fulfillment model: enterprises don't bring goods into their own warehouses first, but suppliers directly ship products to end customers.

-

Applicable Scenarios: Mostly used for finished goods fulfillment; raw materials usually still need to enter factories for production.

-

Main Advantages: Lower inventory holding costs, shorter lead times. In some B2B scenarios, it can significantly improve response speed.

The key to drop shipment is information synchronization. You eliminate one warehouse operation segment, but must use stronger data collaboration with suppliers to maintain controllability.

▍Back Order: Typical Symptom of Supply Chain Pressure

Back Order refers to suppliers unable to deliver on time, causing order backlogs. It's usually the most direct manifestation of supply chain tension.

-

Core Signals: Demand exceeds supply, supplier capacity shortage, raw material shortages, logistics bottlenecks, or scheduling errors.

-

Main Defense: Return to supplier management fundamentals: performance tracking, available backup suppliers, and advance capacity and delivery negotiations.

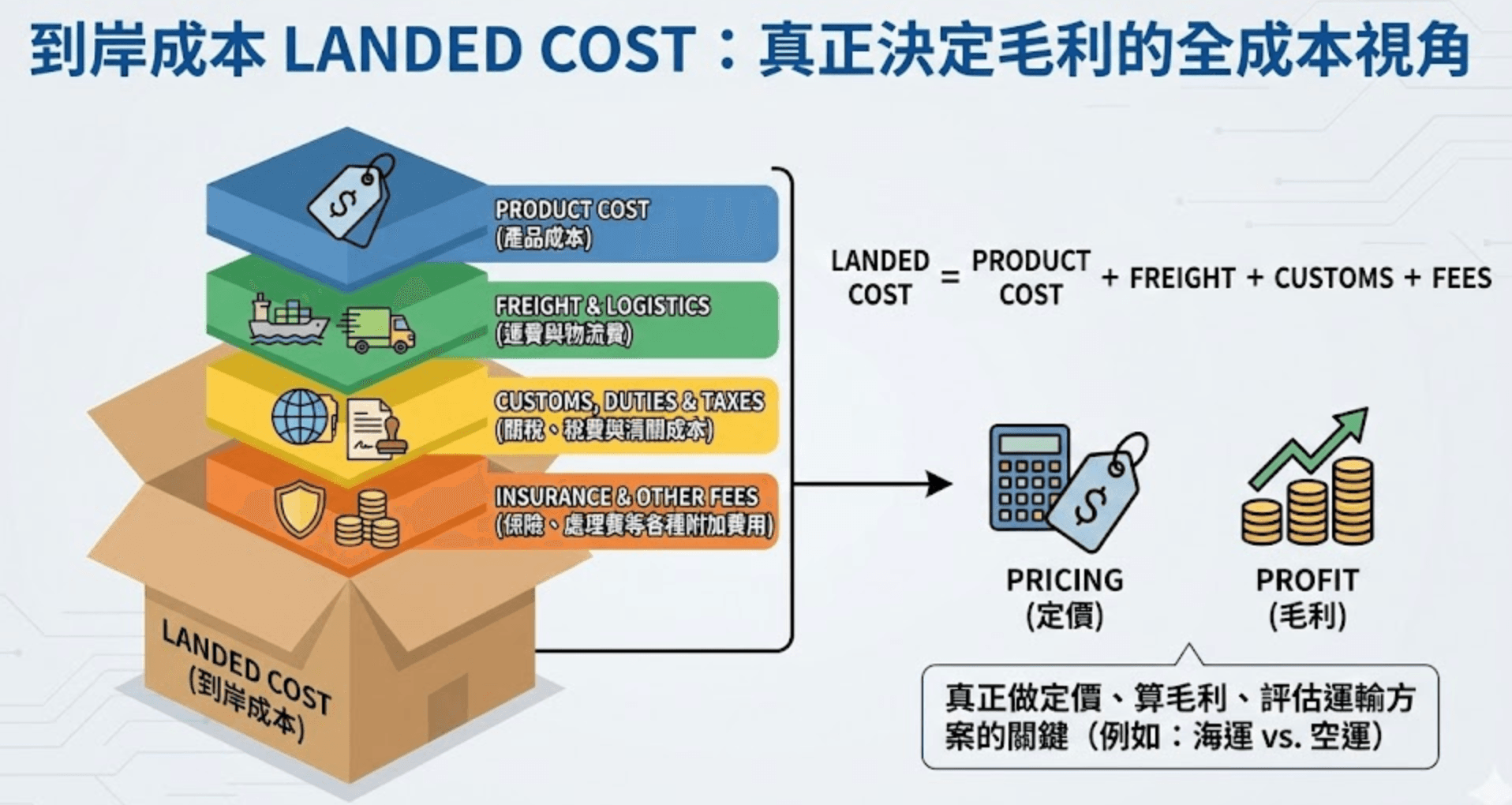

▍Landed Cost: The Total Cost View That Truly Determines Margins

Landed Cost is a financially critical metric, representing the "total cost" of a product from order placement to arrival at your warehouse. It's not just purchase price, but also includes:

-

Product cost

-

Shipping and logistics fees

-

Tariffs, taxes, and customs clearance costs

-

Insurance, handling fees, and various additional charges

Why is it important?

Because only by seeing landed cost clearly can you truly do pricing, calculate margins, and evaluate transportation options. For example: air freight is faster but more expensive, sea freight is slower but cheaper. Whether it's worth trading speed must return to the trade-off between landed cost and cash flow.

Terminology Is the Key Language for Cross-Department Collaboration

Supply chain problems aren't "no one is working in the right direction," but each department using different languages to talk about the same thing. Clarifying basic terms like Procurement, Supplier Management, Inventory, EDI, Logistics, and Landed Cost is like first building the organization's dialogue framework.

When language is consistent, there's a chance for processes to be consistent, KPIs to be consistent, and finally for delivery and trust to be consistent.